Prof. Dr.-Ing. Ingo Gestring

Professor for Production and Logistics Management

Professorship

The Chair of Production and Logistics Management is responsible for teaching in the subjects Supply Chain Management, Production and Logistics Management, Automotive Management and Operations Management.

The professorship's courses are offered in the Bachelor's degree programmes in Business Administration, International Business and Industrial Engineering/Management as well as in the Master's degree programmes in Management of Medium-Sized Enterprises, International Management and Industrial Engineering/Management.

Particular focal points/special areas in teaching are the areas of lean management as well as digitalisation and sustainability of value chains.

Prof. Gestring supervises internships that are completed in manufacturing companies, especially in the automotive industry in the area of production and logistics.

At the professorship, final theses are supervised which are based in industrial companies with a focus on lean production, digital logistics and material flow planning.

Prof. Gestring is responsible as university supervisor for the foreign partner universities Seinäjoki University of Applied Sciences (SeAMK) (Finland), University of Zilina (Slovakia), Škoda Auto University (Czech Republic), Northern Arizona University (USA); Comenius University Bratislava (Slovakia), University Kuala Lumpur (Malaysia), Rotterdam University of Applied Sciences (The Netherlands), Kalinga Institute of Industrial Technology KIIT (India), University of Cape Coast (Ghana), Silesian University Opava (Czech Republic)

Expert activities and Memberships

Accreditation of study programmes:

ASIIN, AQAS, ZEVA in the area of programme, cluster and system accreditation.

Assessment of research activities:

AiF research proposals, review of research activities at colleges and universities.

Memberships:

BVL: German Logistics Association

Asian-German Knowledge Network for Transportation and Logistics

Prof. Dr.-Ing. Ingo Gestring

Rector

- Z 237

- +49 351 462 2543

Sprechzeiten nach Vereinbarung

Response times:

Vita

- 2022-2023 International Experience abroad in Czech Republic, Dubai, Jordan, USA, Ghana, Peru, The Netherlands und South Africa (6 month)

- 2022 Best Teacher Award, Faculty of Business Administration

- From 2015 to 2021 Dean of the Faculty of Business Administration

- 2010-2015 Dean of Studies

- Since 2009 Professorship at HTW Dresden

- 2004-2005 Bentley Motors Crewe, project management vehicle start-up (manager)

- 2002-2009 Volkswagen, various project and line tasks, most recently Director of Production and Logistics at Automobilmanufaktur Dresden GmbH

- 1998-2002 Doctorate (Dr.-Ing.) in process engineering/polymer processing at the Institute of Process Engineering at the University of Hanover, under the supervision of Prof. Dr.-Ing. Dr. h.c.Dieter Mewes

- 1992-1998 Studied mechanical engineering at the University of Hanover, majoring in process engineering, Dr. Jürgen Ulderup Prize for excellent performance in the diploma programme

- 1995-1996 Study abroad at the University of Wisconsin - Madison, USA, DAAD scholarship holder

Interests

The research/interest focus of the Chair of Production and Logistics Management is on lean production and digitisation in the automotive industry.

Prof. Gestring gives lectures on automotive logistics and advises companies on the introduction of production and logistics strategies in companies.

Organised by Prof. Gestring, excursions and lectures by practitioners regularly take place in courses. International excursion destinations are: Midwest of the USA, Slovakia, Czech Republic, Latvia. Once a year there is an excursion lasting several days to an international logistics trade fair coupled with company visits.

![[Translate to English:] Schmuckbild für Veröffentlichungen und Vorträge: Bücher und Schreibzeug](/fileadmin/HTW/Fakultaeten/Wirtschaftswissenschaften/Prof_Ingo_Gestring/Publikationen_Gestring.jpg)

Publications

- Gestring, I.: Digital ideas for the market place in Dittersbach, 2023

- Gestring I.: Logistics Challanges in Germany, Stellenbosch University, 2023

- Gestring, I.: The new German Sustainable Supply Chain Act from differrent perspectives, VDI Landersverband Sachsen, 2023

- Gestring, I.: The sustainability dimension in the transport sector in commodity supply chains, Stiftung Wissenschaft und Politik, Berlin, 2022

- Gestring, I.: Challenges in international supply chains - if the crisis continuous, VDI Landesverband Sachsen, 2022

- Gestring, I, Beranek, M.: Understanding automotive management issues by business simulation, Skoda Auto University, 2022

- Gestring, I., Härdler J.: Supply Chain Management for Engineers, book chapter, Hanser 2021

- Gestring, I.: Supply Chain Disruption, Presentation Rotterdam University of Applied Sciences 2021

- Gestring, I.: Major Players in the Digital World - their Strenths, Weaknesses, Risks and Opportunities, Beyond Horizons: Technology and the Business World in the 21st Century, Skoda Auto University, Mlada Bolelslav, Czech Republic 2019

- Gestring, I.: Digital and lean: CIP workshops in logistics, Conference Poster, 8th Carpathian Logistics Congress, Prag, 2018

- Gestring, I.: Lean und Digital: Shopfloorworkshops in der Logistik, Forum Technische Logistik, Tagungsbeitrag, TU Dresden, 2018

- Ganji, E.; Shah, S.; Coutroubis, A.; Gestring, I.: Towards a Sustainable Demand Chain Framework: Successful Product Development Integration and Drivers, IEEE International Conference on Technology Management, Operations and Decisions, Marrakech, 2018

- Gestring, I.: Life cycle and supply chain management for sustainable bins, Procedia Engineering, Volume 192, 237-242, 2017

- Lenort, R.; Bujak, A.; Gestring, I.; Holman, D.; Imppola, J.; Koziol, A.; Liebetruth, Th.; Soviar, J.; Stas, D.; Wicher, P.: Sustainable Solutions for Supply Chain Management, rw&w new media, Passau, 2017

- Gestring, I.: CO2-Emissions of Spare Parts Distribution, TRANSCOM High Tatras, Conference Poster, 2017

- Gestring, I.: Ethik in Lieferketten, in Gestring, I. et al: Ethik im Mittelstand, SpringerGabler, 2016

- Gestring, I.; Haubold, A.-K.; Gonschorek, T.; Sonntag, R.; von der Weth, R.: Ethik im Mittelstand, SpringerGabler, 2016

- Gestring, I.: Materialwirtschaft, in Gonschorek: Betriebswirtschaft für Ingenieure, Hanser, München, 2015

- Gestring, I: Green Supply Chain Design considering Warehousing and Transportation, International Conference on Sustainable Solutions beyond Mobility of Goods – SustainableMoG, Bratislava, 2015

- Gestring, I.: Automotive Management in Germany, Vortrag Riga Technical University, Riga, 2015

- Gestring, I: Produktionsprozesse systematisch optimieren, in Haubold, A.-K. et al.: Managementkompetenz im Mittelstand, SpringerGabler, 2014

- Haubold, A.-K.; Gonschorek, T.; Gestring, I.; Sonntag, R.; von der Weth, R.: Managementkompetenz im Mittelstand, SpringerGabler, 2014

- Gestring, I.: Production and Logistics in Germany, Vortrag University of Wisconsin, Madison, 2013

- Gestring, I : Modernes Management in deutschen Unternehmen, Vortrag im Bereich der Weiterbildung russischer Manager, Dresden, 2013

- Gestring, I: Einführung eines QM-Systems in deutschen Unternehmen, Vortrag im Bereich der Weiterbildung russischer Manager, Dresden, 2012

- Gestring, I; Zuchold, K: Sächsische Unternehmen und Nachhaltigkeit – eine Bestandsaufnahme, 1. Mitteldeutsche Nachhaltigkeitskonferenz, Dresden, 2012

- Gestring, I : Sustainability and Green Logistics, Vortrag an der VAMK – University of Applied Sciences, Vaasa, 2011

- Schneider, G.; Keil, S.; Wilhelm, K.; Eberts, D.; Stoll, H.; Deutschländer, A.; Gestring, I.: Flow Production at Wafertest. Implementation of Continuous Flow Manufacturing in a Semiconductor Wafertest Manufacturing Environment for Selected Automotive Products. In: 8th Innovationsforum for Automation. Dresden, 2011

- Keil, S. / Lasch, R. / Schneider, G. / Eberts, D. / Wilhelm, K. / Gestring, I. / Deutschländer, A.: Establishing Continuous Flow Manufacturing in a Wafertest-Environment Via Value Stream Design, Proceedings 22nd Annual IEEE/SEMI AMSC Conference 2011, S. 112-118

- Gestring, I : Logistikprozesse eines Automobilwerkes mitten in der Stadt, Fachtagung Automobil-Logistik, Optimierung der Wertschöpfung durch effiziente Logistikkonzepte, München, 2006

- Gestring, I: Philosophie und Konzept der Gläsernen Manufaktur, 10. Fachtagung Fortschritte in der Automobillogistik, Logistik in der Gläsernen Manufaktur, Dresden, 2003

- Gestring, I: Entgasen von Polymeren in Schneckenmaschinen, in Polymeraufbereitung 2002 . technischer Fortschritt zur Steigerung von Leistung und Produktqualität, VDi-Verlag, Düsseldorf, 2002

- Gestring, I; Mewes, D: The Devolatilization of Polymers in a Transparent Double-Screw Extruder, ANTEC 2002, San Francisco, 2002

- Gestring, I; Mewes, D: Degassing during Polymer Processing, Twelfth Int. Heat Transfer Conference, Grenoble, 2002

- Gestring, I; Mewes, D: Entgasen von Polymerschmelzen in verfahrenstechnischen Apparaten, GVC-Dechema-Jahrestagungen 2002

- Gestring, I; Mewes, D: Devolatilization of molten polymers during multiphase flow in double-screw extruders, 2002 Fluids Engineering Division Summer Meeting, Montreal, 2002

- Gestring, I; Mewes, D: Devolatilization of Polymers by Diffusion and Foaming, Journal of Reinforced Plastics and Composites, Vol. 20, 2001

- Gestring, I; Mewes, D: Heat and Mass Transfer during the Degassing of Polymers, 5th World Congress on Experimental Heat Transfer, Fluid Mechanics and Thermodynamics, Tessaloniki, 24.-28. September 2001

- Gestring, I; Mewes, D: Degassing of molten Polymers, Chemical Engineering Science, 2001

- Gestring, I; Mewes, D: Foam Formation and Diffusive Transport during Devolatilization of Polymers; AIChE-Spring Meeting Atlanta 2000

- Gestring, I; Mewes, D: Devolatilization of Polymers by Diffusion and Foaming; ANTEC 2000 Orlando, 2000

- Gestring, I; Mewes, D: Mass Transfer Mechanics during the Devolitization of Polymers; Chisa 2000 Prag, 2000

Field trips/ International activities

Various excursions are offered every semester. Once a year, there is an excursion lasting several days to an international logistics trade fair paired with company visits. In addition, one-day excursions to medium-sized and international companies in Saxony take place.

2022 (planning)

Skoda Auto Mlada Boleslav: 04.04.2022-08.04.2022 (Doing Business and Culture in the Czeck Republic), please contact Prof. Gestring if you are interested.

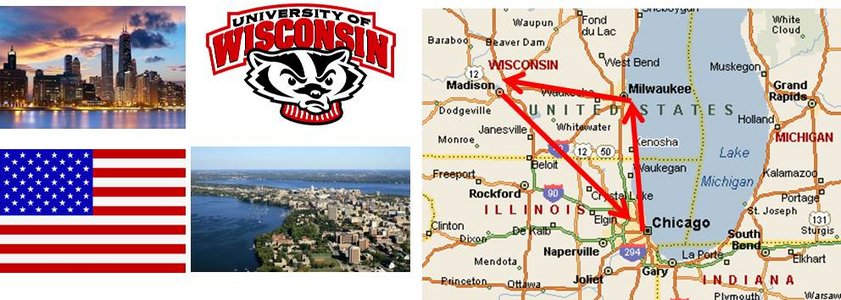

Chicago, Midwest USA (September 2022)

2021 (no excursions, Covid19)

2020 (was planned)

Czech Republic: Course trip with the Master's course "Sustainable Supply Chain Management

2019

Munich: Transport Logistics Fair (beginning of June), study trip with participants of the courses in Supply Chain Management

Mlada Boleslav and Prague: Skoda Auto Uni (end of June)

2018

Chicago: International study trip, Trumpf Smart Factory, German American Chamber of Commerce, Harley Davidson, University of Wisconsin, North Park University

Student excursion to Hanover to the CEMAT logistics trade fair, visit to the VW engine plant in Salzgitter, visit to Müller Milch in Leppersdorf, Inno-Trans in Berlin

China: Beijing, Shanghai and Hangzhou, inauguration of a new concert hall at the Zhejiang University of Science

Prague: Participation in the 8th Carpathian logistics conference

Paris: Visit to the partner university Paris-Nanterre

2017

China: Beijing, Shanghai and Hangzhou with visits to Alibaba, Geely Motors, Jiliang University, Zhejiang University of Science ZUST

Moscow: Visit to the partner university MIIT

Mlada Boleslav: Winter School Green Logistics

2016

Student excursion: Slovakia, Bratislava and Zilina, visit to VW Bratislava and the Slovakian partner universities

Czech Republic: Skoda Auto Uni

2015

Midwest USA; Chicago, Milwaukee and Madison/Wisconsin with Harley-Davidson, Miller Brewery, various companies in Chicago

Riga/Latvia with visits to various companies and the partner university Riga Technical University

2014

Czech Republic: Skoda in Mlada Boleslav

Chamber of Commerce in Prague

Rhode and Schwarz in Vimperk, Bosch and Budweiser

2013

Transport Logistic in Munich with visits to the BMW plant in Landshut, the BMW Group headquarters and the AUDI plant in Ingolstadt

DHL Distribution Centre Leipzig

Axmann Conveyor Technology Zwenkau

2012

Bosch Power Tools plant in Sebnitz

AOA Gauting Dresden (supplier to the aircraft industry)

BMW plant in Leipzig

Elbe aircraft works Dresden

2011

CEMAT logistics fair in Hanover with a tour of the Volkswagen AG plant in Wolfsburg

IKEA Dresden

Automobile factory Dresden GmbH

Transport Logistic trade fair in Munich with a tour of Munich Airport

Supervised Theses

Overview

Each year, Prof. Gestring supervises 40 theses in the areas of production and logistics, supply chain management and process management. 90% of the final theses are carried out in cooperation with companies. The main focus is on students in the following industries and companies during their practical work (exemplary list of various companies):

Automotive industry (Audi, Bentley, BMW, Daimler, Ford, Porsche, Volkswagen)

Automotive supply industry (Bosch, Continental, Denso, ZF Friedrichhafen)

Semiconductor industry (Global Foundries, Infineon)

Mechanical engineering and technology companies (MTU, Siemens, Elbe-Flugzeugwerke)

Logistics service providers (DHL, Schnellecke, Rhenus, Schenker, Hermes)

Consumer goods and food (Kaufland, Kraft, Unilever)

Medium-sized companies (Logsol, Logistikplan, AOA Gauting, von Ardenne, FEP Pirna)

Awards

In recent years, the award in the "Practice" section of the Central German Logistics Student Conference of the Federal Logistics Association was won by students under the supervision of Prof. Gestring.

Internationalisation

Due to the internationalisation requirements of the companies as well as the students, supervised final theses took place in the following regions and countries:

America: USA, Canada, Mexico, Brazil

Europe: Germany, Great Britain, France, Belgium, Netherlands, Switzerland, Austria, Spain, Denmark

Asia: China, Malaysia, India, Thailand, Singapore

Oceania: Australia, New Zealand

- Development and evaluation of improvement potentials for the design of the value chain

- Business process management at Maschinenfabrik Stolpen; an analysis based on the example of cooperation with the Kelly inc company

- Limits of use of e-trucks - An analysis of electric mobility in transport logistics on the basis of economic criteria

- Development of a plan of action for the emergency organisation of automatic systems on the basis of a process FMEAnalysis of the persformance of time:matters`courier partners - What is the current situation of the courier partners performance and how can it be improved in order to enhance customer satisfaction?

- Material flow analysis with elaboration of optimisation measures for material supply

- Evaluation of waste avoidance potentials as well as sustainable transport concepts in the logistics of the Mercedes-Benz plant Bremen

- Digitalisation in the management of operating resources in commercial aircraft production - selection, implementation and safeguarding of an intelligent tool management system

- Development of a key performance indicator system to measure the performance of the supply chain in B2C e-commerce using the example of Tchibo GmbH

- The impact of Brexit on the choice of the warehousing concept for the gear and clothing company Fox Racing

- Optimisation of the procurement process at Senorics GmbH

- Transparency in the supply chain of Cobalt through blockchain technology

- Outsourcing of logistics services in the semiconductor industry: development of an evaluation model for service provider selection decision-making and creation of performance reporting to measure service provider activities

- Make or buy decision on the basis of a production process taking into account business management aspects using the example of Novaled GmbH

- How should companies adapt their IT sourcing in view of the impact of the COVID-19 pandemic?

- The use of hydrogen-powered trucks in automotive logistics

- A literature analysis of recommendations for action in the implementation of digital applications

- Youth tourism concept for a target group-oriented product portfolio

- The extension of the classic value stream methodology to include disprutive technologies in intralogistics

- Generation of a scheme for the determination of required master data/output data for the creation of new logistics and layout concepts

- Process analysis and conception of recommendations for optimising the quality assurance of purchased parts using the example of Mühle Glashütte GmbH

- The carsharing Industry in Germany

- The optimisation of packaging in the field of tension between logistics and marketing

- Behavioural Intention and The Acceptance of Near Field Communication in Mobile Payment Technology: The Case of Students in Dresden

- Analysis and design of a planning and control system based on the CON WIP method

- Blockchain Technology's Effect on Sea Food Supply Chains regarding the Key Supply Chain Management Objectives

- Critical analysis of the article management of a special machine manufacturer and development of a recommendation for action with a process-technical target concept

- Digital implementation of the SQCDP tool for the A350 XWB door production of Airbus Helicopters Deutschland GmbH at the Donauwörth site

- Analysis of the existing processes in the context of repackaging operations for product raw materials and development of strategic recommendations for action for process improvement using the example of Robert Bosch GmbH in Homburg

- 3D printing in small batch production - economic and technological evaluation using the example of the start-up company Triebfeder GmbH

- Material flow analysis and optimisation of the factory layout of the assembly of a printing machine manufacturer by means of mathematical-graphical solution methods

- Application of the LEAN management system SYNCHRO in the product qualification of machine tools

- Development of a concept for sustainable inventory management - anonymous example of an automobile manufacturer in Mexico

- Optimal and efficient initiation processes for cooperation in the aviation industry - an analysis using the example of Saxon aviation companies

- Implementation of improvements to enhance logistics delivery quality at the example of an automotive manufacturer

- Altruistic efectiveness in nonprofit organisations

- Strategic business analysis for a medium-sized cooperation in Germany and China

- Attractiveness of the Arab region for German companies

- Integration of door production into the process flow of combi steamer production

- Elimination of raw casting priming of planetary carriers and axle drive housings - a value stream oriented potential analysis

- Piloting a cyber-physical employee assistance system in the chemical industry - a socio-technical case study on platform-controlled wearables

- The Key Performance Indicator System as a Management Tool for BMW Supply Centres

- Development of an analytical method for comparing storage systems for pallet storage in early planning phases

- Implementation of multi-channel distribution in retail and the impact on warehousing. Case study: Apparel industry

- Development of a future-proof production approach for an SME with one-off and batch production

- Data collection and processing with subsequent scenario analysis within the framework of a simulation study in project-oriented production

- Creation of a concept for the introduction of the SEMI E10 standard and for the calculation of the overall equipment effectiveness (OEE) at TRUMPF Photonic Components

- Concept for optimising internal warehouse processes in the areas of incoming goods, intralogistics and shipping

- Concept development and evaluation of a VR training in the area of Porsche production system

- Al explains himself, a review of existing approaches for applications in semiconductor supply chains

- Comparison of Lean and Agile Supply Chain concepts

- Augmented Reality as support in the area of after-sales service using the example of the company Trumpf

- Implementation of a calculation tool for capacity planning in the packaging sector of Robert Bosch AG Hallein Austria

- Development of a concept for the implementation of Kanban in the information technology department at Eberspächer Exhaust Technology Wilsdruff GmbH

- Possible applications of unmanned aerial vehicles for spare parts and emergency supply - A market research for the development of application concepts

- Preparation of a recommendation for action for the use of digitalisation potentials on the basis of an analysis of the production process in natural stone processing

- Development of a framework contract concept for the transport of end products of AMTC GmbH & Co.KG

- Concept development for wheel assembly at Porsche Leipzig GmbHIntegration of driverless transport systems at an OEM of the automotive industry under consideration of the economic efficiency in comparison to conventional transport systems

- Optimisation of industrial trucks in infrastructural logistics: Development of a sales concept for the Fleet Analysing System (FAST) of LOGSOL GmbH

- Creation of a calculation tool for the quantitative determination of personnel requirements in the production warehouse of Robert Bosch Produktie N.V. Tienen Belgium

- Conception of a small batch production with the help of holistic production systems using the example of Bike24 GmbH

- Influence of digital structures on the ordering process of the Lidl shop

- Digital process optimisation in logistics using the IT system DALI

- Use of cognitive systems in supply chain planning

- Trends in intralogistics using the example of the logistics service provider Schnellecke Logistics Sachsen GmbH at the Dresden location

- Supply chain management - optimisation of the supplier structure for CLOUD&HEAT Technologies GmbH

- Conceptual design of a reference process for truck control and dispatch in the incoming goods department of the BMW plant in Leipzig

- Recalculation of order quantities in an e-commerce company for bicycle, outdoor and sports articles

- The Reduction of Tail Spend through the Implementation of an Integrator

- Comparison of Order Picking Systems under the Aspects of Material Flow System, Information System and Organisational System

- Risk Management Tools in the Purchasing Process

- Investigation of Production Control for the Planned Use of a Detailed Planning Tool at the Automotive Supplier Eberspächer at the Wilsdruff Location

- Costumer-oriented measures to achieve costumer loyalty with the focus on a logistics controlling concept in Contract Logistics at Dachser Netherlands B.V. Logistics Centre Rotterdam

- Possible applications of smart glasses in order picking using the example of a demonstration object

- Partial analysis of the material unit cost deltas of CNG-specific components with derivation of cost efficiency potentials for future vehicle projects

- Analysis and optimisation of the implementation process of a new courier partner to the network of time:matters

- Process Improvement with regards to the Employee Offboarding Process in Siemens Malaysia including a benchmark with Siemens Germany

- Influence of global agreements on the B2B-relationship and how to maximize benefits for both parties

- Potential benefits of supply chain visibility for increased customer satisfaction using the example of Anheuser-Busch InBev

- Reduction of trade working capital in indirect purchasing

- Process optimisation for cost reduction of washed parts using the example of shafts from Robert Bosch Automotive Steering GmbH

- Concept study: Digitalisation potential in the automotive supply industry-Kanban 4.0

- Development of a methodology for the visualisation of the determination and presentation of existing key figures and the optimisation of the recording process using the example of an efficiency key figure in the logistical foreign supply of BMW AG

- Development and implementation of a demonstration object for the presentation of electronic Kanban for the University of Applied Sciences Dresden

- Intralogistics - Implementation of drones

- Analysis of the actual situation of the tool "Strategic Resource Management" of AUDI AG for its suitability as an instrument of strategic and quantitative personnel planning

- The Balanced Scorecard as a management and measurement toll for the trasition towards strategic Business Partnering within the Procurement function at Novo Nordisk

- Development of a manual for packaging planning in the automotive sector

- Comparison of the environmental footprint of plastic and wooden EURO pallets using life cycle analysis (LCA)

- The conceptual design of picking systems for order picking processes

- Implementation of an AutoID technology in a medium-sized production company using the example of an RFID introduction at Eberspächer Exhaust Technology Wilsdruff GmbH

- Application of the LEAN management system SYNCHRO in the product qualification of machine tools

- 3D printing in small batch production - economic and technological evaluation using the example of the start-up company Triebfeder GmbH

- Material Flow Analysis and Optimisation of the Factory Layout of the Assembly of a Printing Machine Manufacturer by Means of Mathematical-Graphical Solution Methods

Winter semester 2025/26

- Compulsory module in the study programme W72 - Business Administration and Engineering

in the 3. semester

- Compulsory module in the study programme W72 - Business Administration and Engineering

in the 2. semester

- Compulsory module in the study programme W72 - Business Administration and Engineering

in the 2. semester

- Compulsory elective module in the study programme W74 - International Business

in the 3. semester

Summer semester 2026

- Compulsory elective module in the study programme W74 - International Business

in the 4. semester

- Compulsory elective module in the study programme W74 - International Business

in the 4. semester in the field of study "General and Marketing Management"

- Compulsory elective module in the study programme W74 - International Business

in the 4. semester

- Compulsory elective module in the study programme W72 - Business Administration and Engineering

in the 1. semester