Making digitalisation tangible at the Industrial IoT Test Bed

What is an Industrial IoT Test Bed?

“Making digitalisation tangible” is the slogan of the Industry 4.0 Model Factory, which was set up - under the direction of Prof. Dirk Reichelt - by the University of Applied Sciences (HTW) Dresden. This Industrial Internet of Things (IIoT) Test Bed is a research and evaluation infrastructure for IoT solutions in a manufacturing environment.

The IIoT Test Bed was funded by the Federal Ministry of Education and Research (BMBF), it involves a discrete manufacturing process and all typical components of an industrial program. With this, a realistic simulation of complex production and logistical processes is possible.

In addition to tasks in research and development, the IIoT Test Bed serves as both a demonstrational and informational platform. For this purpose, we developed the concept of a stationary and permanent Track and Trace Theatre, in cooperation with the AIM-D e.V. In our guided tours we will inform you about current research projects and show you the possible applications of Industrial IoT key technologies with practical demonstrators.

SHOWROOM

University of Applied Sciences Campus Central Building

Zentralgebäude Z 903

Friedrich-List-Platz 1

01069 Dresden

Benefits of the Industrial IoT Test Bed

The Model Factory addresses decision-makers in administration, politics and economics in different branches. The main target audiences are companies and their executives as well as employees looking to introduce digitization and IoT solutions. The Industrial IoT Test Bed is a useful platform for projects such as:

- Development of new products and business models based on different automation and digitalisation technologies

- Testing of innovations in a complex manufacturing environment

- Optimization of products, services, processes and manufacturing procedures

It aims to strengthen long-term competitiveness for companies, primary small and medium-sized enterprises (SMEs) to international standards.

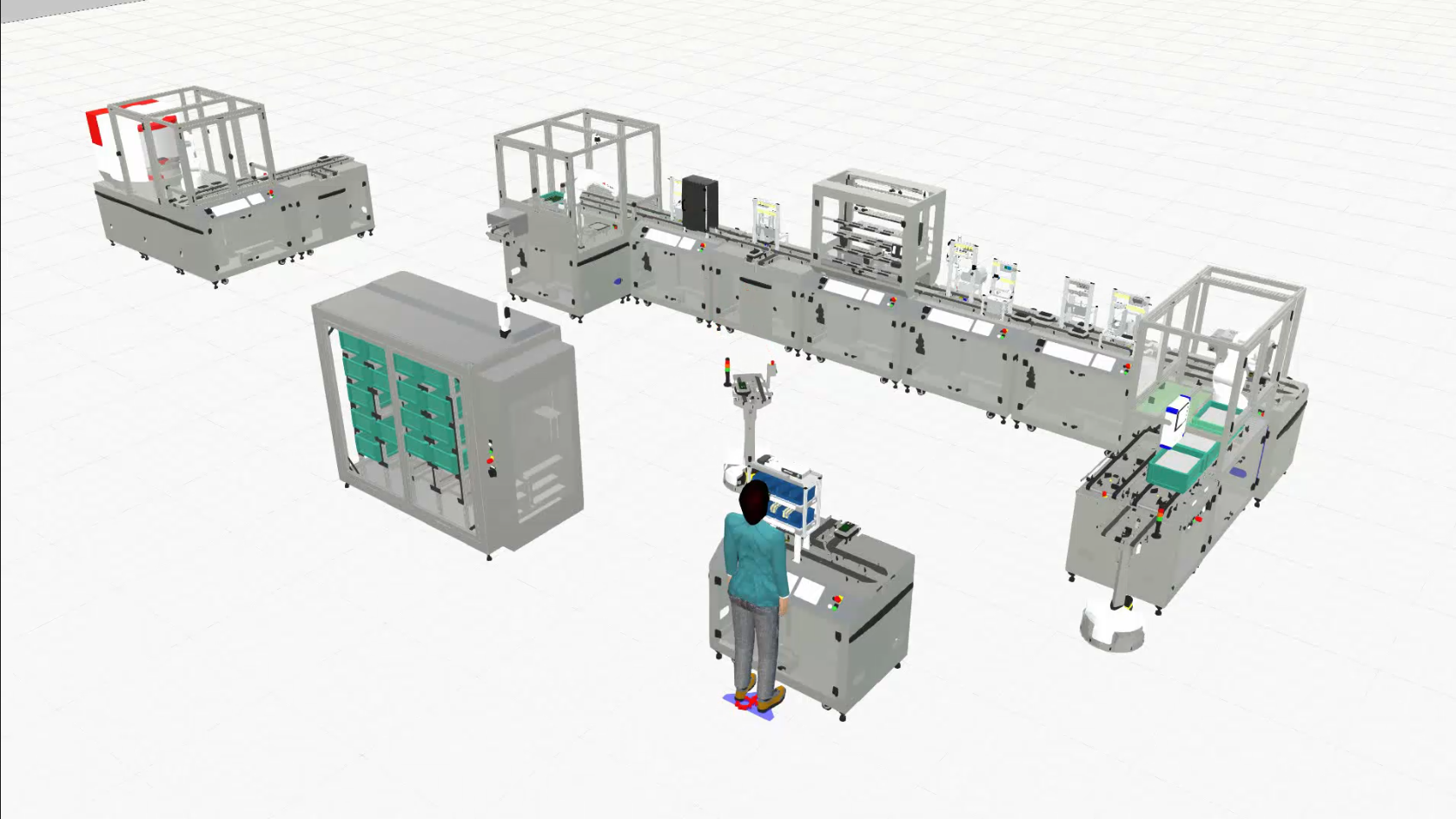

What does the room concept of the Industrial IoT Test Bed look like?

- Accommodated in the central building, 9th floor of the University of Applied Sciences (HTW) Dresden

- Usable area of approx. 250 m2

- Connected training/workshop room and the Smart Factory

- Supplied with all engine and media necessary (compressed air, high voltage current, network, etc.)

Contact

Equipment Available to the User

- Robot assembly and loading cells

- Various application modules

- Manual workstation with pick-by-light system and CoBot workplace (within Q2 / 2018)

- Autonomous transport vehicles "Robotinos"

- CNC milling machine with automatic loading and unloading

- High-bay warehouse with an energy recovery system

- Energymonitoring

- ABB Cobot "YuMi" at the manual workstation

- Universal Cobot „UR3“ with several gripping devices

- 2 industrial robots

- pneumatic and electric gripper

- linear transport system

- intelligent tool station

- light grid for flexible anclosure of the robot cell

- Wireless transmission technologies (LiFi, WiFi, Bluetooth, IEEE 802.15.4, UWB)

- location technologies (RFID, Bluetooth, IEEE 802.15.4, UWB)

- Controllers Siemens S7-1500 / Festo CECC / Beckhoff CX 5310

- OPC-UA interfaces

- Adaptive lighting control - Human Centric Lighting

- Rhebo Industrial Protector

- IoT components

- Robotron RoboGate

- Bosch XDK 110

- Wireless Sensor Nodes (IEEE 802.15.4 based)

- Kunbus Revolution Pi

- Dialog IoT Sensors

- RFID-Sensortransponder

- Festo CPS-Gate

- AIS Equipment Cloud with Gateware from AIS Automation Dresden GmbH

- InSys iCom Gateway with Cloud from "Dinge der T-Systems Multimedia Solutions GmbH"

- Digalox 4.0 measuring device platform from TDE Instruments GmbH

- IoT-Sensors from Pepperl+Fuchs

- Augmented/Virtual Reality Solutions

- HTC VIVE

- Oculus Rift

- Microsoft HoloLens

- Manufacturing Execution System (MES)

- Enterprise Resource Planning System (ERP)

- Big Data Storage/ Data Lake (Hadoop Cluster)

- Energy Management Solutions

- 3D Simulations Software

- Siemens NX

- Visual Components

- Cloud solutions (Azure, Bluemix, AIS Equipment Cloud, "Cloud der Dinge", AWS)

- OPC-UA Frameworks (ProSys OPC-UA SDK, Unified Automation)

- ABB Robot Studio

- LabView

- AutoDesk Inventor

What advantages does the Industrial IoT Test Bed offer companies?

- Acces to infrastructure and equipment of the Industrial IoT Test Bed

- Expertise in digitization and IoT solutions provided by the SPS task force

- Networking and collaborative platform for companies

- Demonstration of different IoT solutions alongside internal processes

- Joint development of demonstrations and prototypes for Industrial Internet solutions

- Expand the range of customers by live demonstrations

- Realization of optimization potentials such as saving of manual data acquisition

- The increase of informational transparency in real time

- Comprehensive production of product information

Weitere Dokumente/ Antragsformulare finden Sie hier: https://www.htw-dresden.de/en/university/facultys/info-math/research/smart-production-systems/industrial-iot-test-bed

What services and offers do we provide?

- Design and simulation of industrial IoT solutions

- Research and development services for developing individual process and product innovations

- Support for sustainable, digital transformation including consulting and strategy development

- Demonstration and information in the context of workshops, training courses and free guided tours in german

Weitere Dokumente/ Antragsformulare finden Sie hier: https://www.htw-dresden.de/en/university/facultys/info-math/research/smart-production-systems/industrial-iot-test-bed

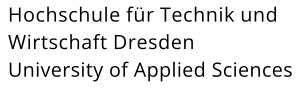

Simulation of the Industial IoT Test Bed

Digital twin of the Industrial IoT Test Bed, created by DUALIS GmbH

When to contact the University of Applied Sciences (as a Company)?

This list does not claim to be complete. These are just a few examples of applications.

- Conception and prototypical realization of Cyber-Physical-Production-Systems

- Solving technical software problems including associated interfaces

- Development and testing of demonstrators in an industrial manufacturing environment

- Introduction of business information systems to control the manufacturing and resource management

- Elaboration of new concepts in operational automation and information processing

Weitere Dokumente/ Antragsformulare finden Sie hier: https://www.htw-dresden.de/en/university/facultys/info-math/research/smart-production-systems/industrial-iot-test-bed

![Gefördert vom BMBF - Bundesministerium für Bildung und Forschung [Translate to English:] Förderung durch das BMBF](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Logos/BMBF_CMYK_Gef_L_300dpi.jpg)

![Förderprogramm Forschung an Fachhochschulen [Translate to English:] Förderung durch Forschung an Hochschulen](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Logos/Forschung_FH.jpg)

![[Translate to English:] Logokombi Saxony5 und CCL Fabrik der Zukunft](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Logos/S5_TV3_CCL_FaZ_Comb_RGB_Bild.jpg)