Research and Development Projects

Current Research Projects

Clever

CLEVER is developing a range of hardware accelerator, design stack and middleware innovations that are revolutionising the ability of edge computing platforms to federate and utilise sparse resources.

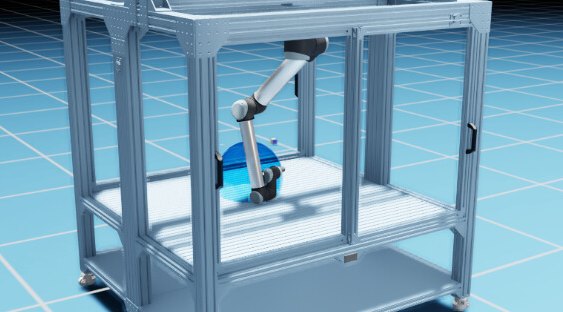

ICV - Industrial Computer Visio

Within the ICV project, the testing of the diverse visual inspections in production is to be evaluated with the help of computer vision.

KiWi

The project "KiWi - AI workshop: for transfer to the economy" aims to strengthen the role of the HTW at the Dresden location in order to create, consolidate and bundle skills and abilities in the field of AI in the long term.

LOTSE

Together with Globalfoundries, the LOTSE project is researching and developing new methods to be able to deliver on time at all times in semi-conductor production, even with short-term and frequent order changes.

![[Translate to English:] Kompass mit diversen Symbolen der Produktion](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Projekte/AdobeStock_143394752.jpeg)

OSHOP

The OSHOP project places the concept of Open Source Hardware (OSH), freely accessible blueprints for physical components, devices and machines, at the center of the research transfer.

![[Translate to English:] offene Leiterplatine auf einem Werkstückträger](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Projekte/My_project-_Open_Hardware_Werkstuecktraeger-1.png)

Junior Research Group ProMenTaT

The focus of the junior research group "Production Systems with Humans and Technology as a Team" (ProMenTaT) is research into the roles and tasks that people assume as individuals in future production systems.

Semiconductor-X

The “Semiconductor-X” project aims to develop digital twins for the semiconductor industry based on the Gaia-X/Catena-X architecture, which digitally map the planning-critical segment of the supply and value chain.

![[Translate to English:] Einblick in eine Halbleiterfertigung](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Projekte/Kopfbild_Semicunductor_X.png)

Future Mobility

The joint project Future Mobility, led by Infineon Technologies Dresden GmbH & Co. KG aims to develop innovative solutions for future automotive electronics along the entire value chain.

KISS-MINT

Creative, interesting, playful Sensitization for MINT (Mathematics, Sciences, Informatics and Engineering) in cooperation with Dresden schools, the HTW Dresden is developing new experiments for everyday school life with the Calliope Mini.

Lab X - the Start Up Lab

The Lab X project will create an Interdisciplinary Idea Workshop for prototyping and for exchanging and developing ideas to promote startups.

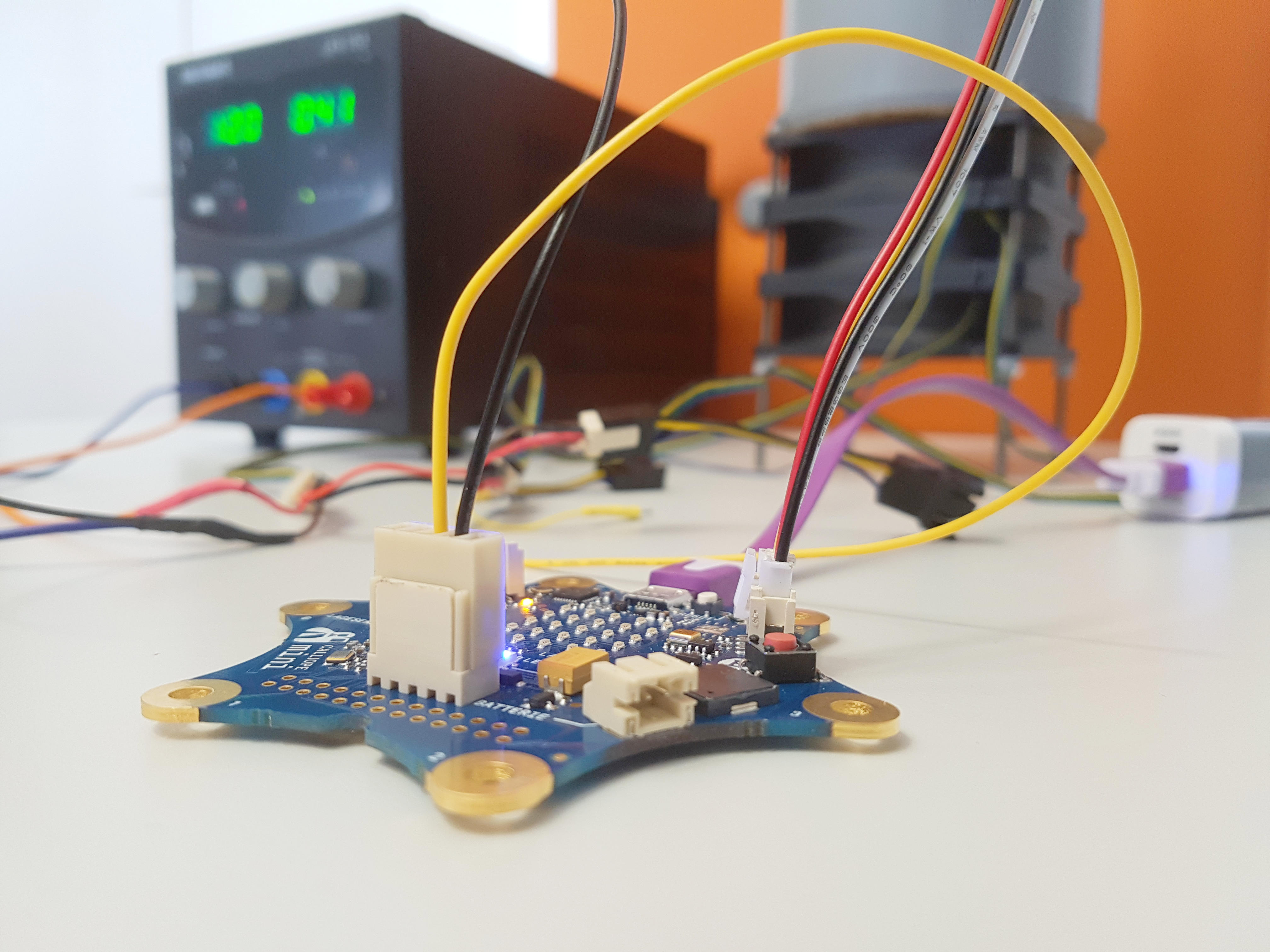

OSHIE

The OSHIE project aims to investigate the use of free and open hardware for scientific tasks for the scientific system.

P3S2

P3S2 stands for personal, portable and preventive protective system. The aim is to investigate the addition of sensory, actuator and communicative capabilities to traditional personal protective equipment.

![[Translate to English:] verschiedene Schutzausrüstung für Feuerwehrleute](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Projekte/Kopfbild_P3S2.png)

Saxony5 transfer field "Production"

The transfer field "Production" in the Saxony5 transfer network deals with the topic "resilient manufacturing".

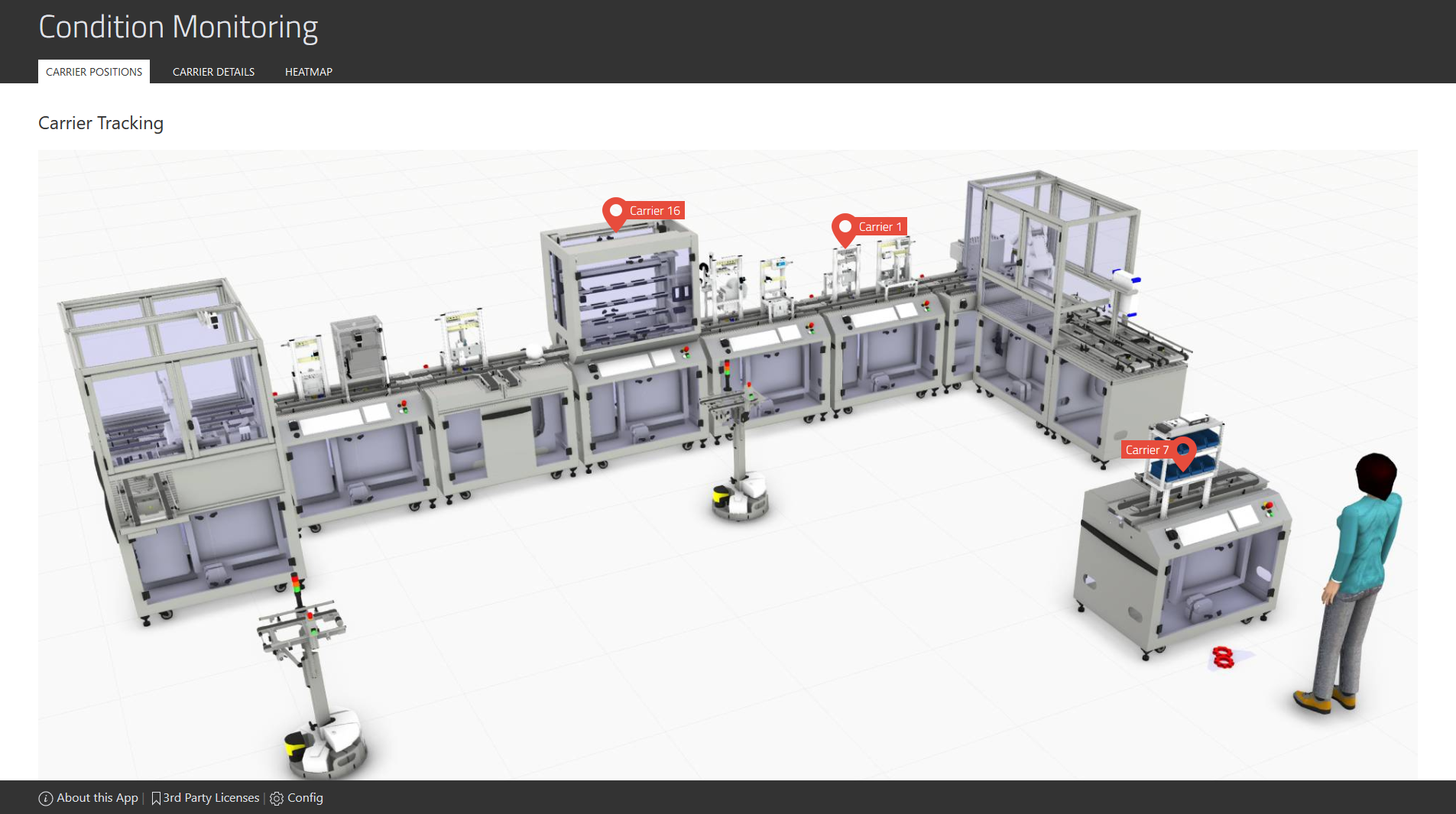

Industrial Internet of Things Test Bed

The project has created a central laboratory and research infrastructure that can be used for interdisciplinary research and development of industrial IoT concepts and solutions in teaching and practice.

Completed research projects

The aim of the project “Automated Generation of Robust Synthetic Image Datasets and AI Models for Computer Vision Applications” (ASYN4CVA) was to develop a consistent process for the automated generation of synthetic data and the creation of a robust object recognition model for customer-specific products. This process should make it possible to automatically generate robust object recognition models for various industrial applications.The models trained in this way were suitable, for example, for implementing object recognition for user guidance during maintenance and repair work on industrial plants, or for creating object recognition models for quality assurance in industrial processes to detect missing, incorrectly assembled, or additionally assembled parts.Other areas of application for these models included image-guided control of industrial robots for pick-and-place or assembly tasks. The method generated synthetic image data based on digital models or real objects in an automated workflow and used it to train CNN models.

In production engineering, enormous amounts of data are generated every second and processed internally in the manufacturing machines. This data contains valuable information about the current status of the machine, tools, and product and could increase the value-added potential of the machine and associated services through targeted evaluation. In practice, however, this data has not yet been comprehensively evaluated or made available digitally for downstream applications, whether internal or external to the company. The reasons for this lie, on the one hand, in the high demands that data acquisition and provision place on machine-related hardware and software. On the other hand, investments in digital infrastructure are associated with unclear amortization for customers and risks to intellectual property and know-how. At the same time, although the manufacturers of the machines and their components have the necessary know-how to design data-driven applications, they lack access to the data of their products during ongoing operation at the customers' sites. GAIA-X has created a framework in which data-driven applications can be implemented in compliance with data protection and data sovereignty requirements. The Fed-X-Pro project uses GAIA-X's cross-domain and cross-company data infrastructure to implement universally applicable applications for increasing value creation in production technology.

Practical partners

- Fraunhofer Institute for Machine Tools and Forming Technology IWU (project coordination)

- VPD Vakuum- und Präzisionsteilefertigung Dresden GmbH

- GROB-WERKE GmbH & Co. KG

- Gühring KG

- UKM Technologies GmbH

- Katulu GmbH

- Simplifier AG

What is WAPRO

Adaptable companies that can react agilely to disruptions in value networks and their production systems are a key to a crisis-proof economy. In the future, Saxon companies must be enabled to recognize risky changes in time and to evaluate them. Their production systems must be able to respond to these changes in a flexible and agile manner.

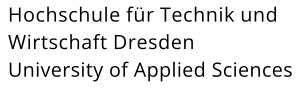

To achieve the adaptable capability of a production system, five change enablers (universality, mobility, scalability, modularity and compatibility) are proposed in the literature. It is necessary to investigate these enablers with respect to their operationalizability for production systems of Saxon SMEs and to derive suitable methods for the implementation of adabtability. The REACT research group "WaPro - Wandlungsfähige Produktionsumgebungen" pursues a holistic research approach, which combines the adaptability to achieve from the perspectives of people, technology and organization. To this end, the impact of digital change on socio-technical production systems in manufacturing SMEs is being researched. In doing so, the research group qualifies future specialists for Saxon science and industry to research and design transformational production environments as socio-technical systems that contribute to the preparation of a green, digital and stable recovery of the economy.

The aim

WaPro aims to qualify young scientists to develop concepts for the restoration and further development of a stable, digital and green Saxon economy. Through the research group, new concepts for the realization of transformable production systems for discrete manufacturing are explored in an interdisciplinary approach. The project results will strengthen the innovative power of the Free State of Saxony in the field of transformable SMEs. To this end, the research group links the disciplines of computer science, business informatics, industrial engineering, business administration, media informatics and labor sciences.

Derived from the core goals of "stable, green and digital", the young scientists are investigating the transformation enablers of universality, mobility, scalability, modularity and compatibility with regard to their suitability for operational implementation of the goals at the four levels of inter-company collaboration (networked value creation), factory planning, machine/plant and human-technology interface. A major focus is on the operationalizability of the enablers for manufacturing SMEs in Saxony.

On the content, methodological side, the goal is to generate synergies through cross-disciplinary collaboration between the individual sub-disciplines and to sensitize and motivate the young scientists for cross-disciplinary and cross-methodological collaboration and for the creation of innovative solutions for transformation-capable production systems.

Tools for the engineering of digitization solutions

The Arrowhead Tools project targets digitization and automation solutions for European industry. The technological gaps that hinder IT/OT integration are to be closed by introducing new technologies in an open source platform for design and runtime engineering of IoT systems. The sub-project of HTW Dresden includes the realization of use cases for interoperability between secure SMART industrial applications. Task areas in terms of content include production support, energy efficiency, task management, data analytics and smart maintenance/ servicing.

The project "Capabilities-bAsed and Self-Organizing Manufacturing Management" (CASO) aims to develop a software framework that supports the production planning and control of such a smart factory by means of combined centralized and decentralized planning and enables the secure connection of production capacities of contract manufacturers. The project investigates the combination of self-organization and central production planning in a smart factory, the possibility of describing machines by means of semantic models, the dynamic generation of plant recipes based on this, and the digital safeguarding of recipe data to protect against product counterfeiting and the protection of intellectual property in the case of third-party production. The project is being carried out in cooperation with the practical partners: adidas AG, TecWare Gesellschaft für Softwareentwicklung mbH, DUALIS GmbH IT Solution, Tobias Prometall GmbH & Co. KG and Carl Zeiss Innovationszentrum für Messtechnik GmbH.

SmaRTHI stands for Smart Robotics for time-flexible, immersive and location-independent teamwork in craft and industry and is a joint project of TU Chemnitz, TU Dresden, HTW Dresden and Fraunhofer IWU gewesen within the framework of the Future Cluster Initiative (Clusters4Future) of the Federal Ministry of Education and Research. The goal: humans and robots working more closely together to increase the competitiveness of craft and industry. The vision of the SmaRTHI future cluster is for humans and robots to work together in the future as optimally complementary time-flexible and location-independent teams. In this way, better working conditions can be created, people can be protected in their manual activities, participation in the labor market can be democratized, and the shortage of skilled workers in the skilled trades can also be countered with the new technologies. At the same time, factories and businesses will become more efficient, flexible and resilient. As a result, the overall prosperity of society can be increased. SmaRTHI is building an ecosystem in which novel technologies are researched, developed and industrialized. Digitization as a connecting element is increasingly helped to have a value-creating effect in physical processes.

Current information on the research alliance can be found here on the web: https://www.smarthi.de/

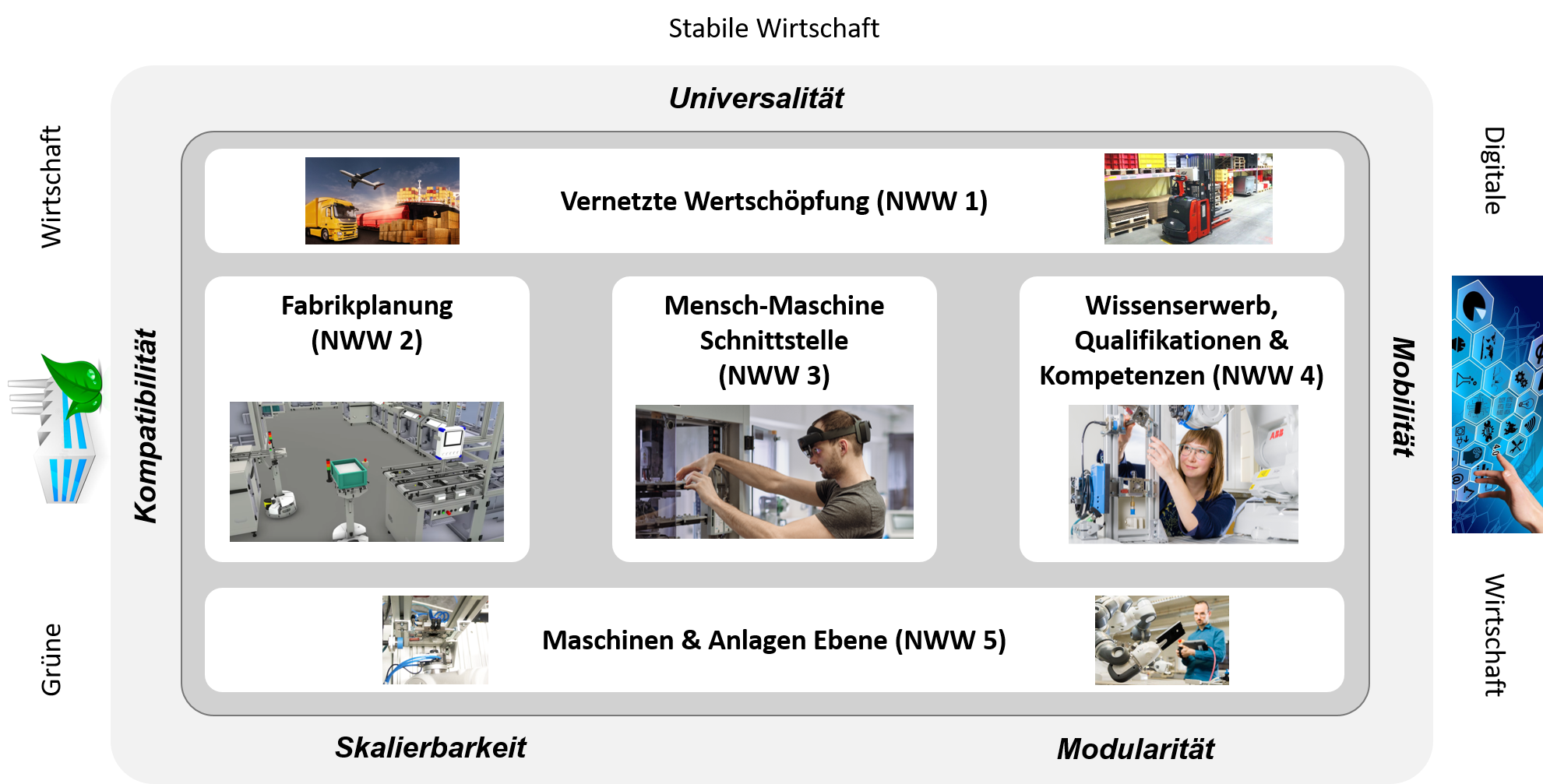

Intelligent automation of the tire mounting process

Motivation and objective

The aim of the project is to ensure continuously high quality, increase quantity and thus increase customer satisfaction through smart automation of the tire assembly process. To this end, the project is developing functional models and demonstrators that enable automation of the assembly process using equipment already used in assembly today. These systems will be extended by sensors and actuators in the sense of a retrofit approach. With such a system, the physically heavy work is shifted from the employees to the automatic assembly machine and very high, consistent quality as well as higher throughput is possible.

Subproject: Software systems and test environment for the RFID sensor tag platform.

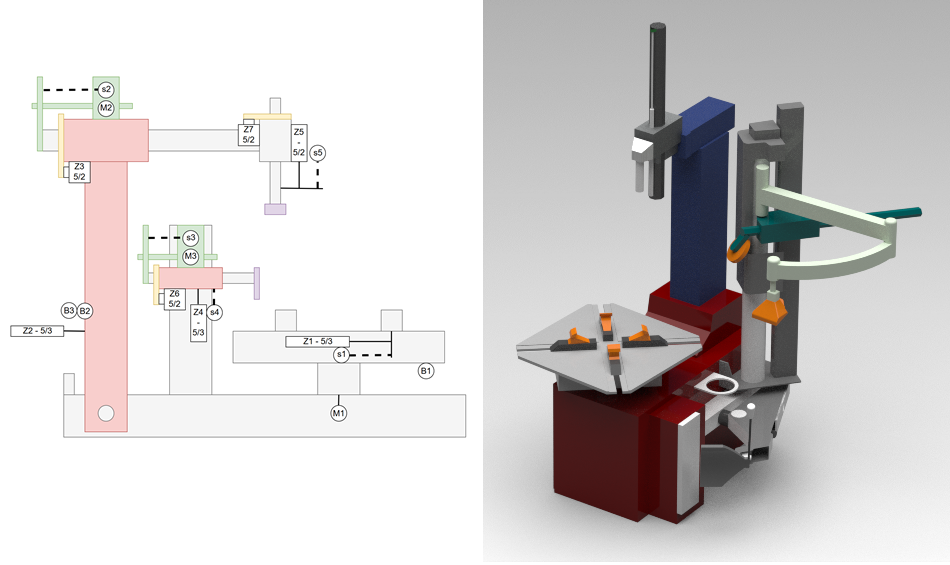

In RISE4PM new methods for the use of wireless RFID sensor systems for the realization of Industrie 4.0 use cases are investigated. For this purpose, new approaches in the form of cyber-physical systems for production will be researched and developed. The result will be a holistic framework of a cyber-physical production system (CPPS) consisting of hardware and software components, which will enable industrial users to efficiently realize typical measurement tasks for Industrie 4.0 use cases following a plug-and-work approach using RFID technologies.

Project Transfer Center Functional Integration for Micro/Nanoelectronics - Subproject SimiKom - System integration of miniaturized components for structure-integrated wireless sensor technology in mechanical engineering.

In cooperation with Fraunhofer IPMS, HTW Dresden is developing a wireless data logger with an RFID sensor interface using the technologies developed in SimiKom, which can be seamlessly integrated into the material flow in a manufacturing system (e.g. by attaching it to the component or as a separate "job" in the system). For this purpose, the project develops and tests new software architectures for the efficient acquisition and processing of sensor data. Another focus of the work is the development of a management shell for the data logger and the overall system for seamless integration into operational information systems and industrial control systems.

Modern teaching requires access to learning resources and content independent of time and place. Currently, these learning environments are primarily limited to digital content and formats. The "Ubiquitous learning environment for cyber physical systems" (ULE4CPS) project has enabled new forms of interaction in teaching and learning on cyber-physical systems (CPS). CPS are systems in which information and software technology are connected with electronic and mechanical components. While working with digital twins and virtual commissioning is becoming increasingly important in practice, little work exists that transfers these concepts for application in higher education. The project aims to provide, in addition to face-to-face teaching for learners, access to complex technical systems at any time and any place. The goal was to create a learning and experimentation environment that enabled mental and physical immersion in complex information technology and physical systems, independent of time and place.

The ULE4CPS project was funded as part of the Stifterverbandes, anniversary initiative "Wirkung hoch 100" (Impact to the power of 100), as one of the 100 most outstanding ideas for better education, science and innovation.

To individually determine the digital status of a company (digital maturity level), the self-assessment tool of the same name was developed as part of the self-assessment tool of the same name. This tool offers In addition to the assessment of the digital maturity level, it also offers suitable, target-oriented recommendations for action, which are illustrated by designed demonstrators and explanations. This to make it easier for companies to get started with digitization. More information on DigiLotsen and access to the tool can be found here.

Motivation

Modern production plants are nowadays unimaginable without robots. High reliability, low downtime and working in hazardous areas make robots the guarantee for fast production in high volumes. Robots are said to be destroying jobs. However, practice shows that this is not the case. On the contrary, they create jobs. The current trend is that production processes are becoming much more individualized in the course of the digitalization of the industry. Robots have not been able to cope with these frequent changes yet, so they have to be constantly reprogrammed. The resulting implementation process is very complex, expensive and lengthy. Current market figures show that approximately 56% of the costs of automating a previously manual activity are incurred by implementing the necessary software. The costs for automation can rise to a level where it is no longer worthwhile.

Above all, the adaptability of people and their ability to solve problems creatively are indispensable for today's production facilities. Robots should rather be used to facilitate the work of humans. This allows them to do the part of the work that is particularly difficult, dangerous or monotonous. To achieve this, robots must be enabled to collaborate with humans quickly and adaptively. So-called Cobots are capable of exactly that. The advantage of collaboration is that transfers between manual and automated production steps can be carried out directly and, under certain circumstances, collaborative manipulations are also possible. The field of human/robot collaboration is currently still largely ignored. The implementation and establishment of this key technology would keep local companies competitive on the international market and secure jobs in the long term.

Objective

Within the project a demonstrator shall be developed and integrated into Industrial IoT Test Bed, which enables the cooperation between a Cobot and a human at a manual workstation. In order to counteract the high cost and time factor in robot programming the solution of consortium leader Wandelbots GmbH is used. That enables non-programmers to train industrial robots with the help of intelligent clothing and gesture recognition without having to write program code. Therefore the technical integration of the sensor clothing, the Cobot control and the RTLS with a production control system is to be developed and tested. The result is a demonstrator which, in the interaction of sensor information from the clothing, information from the RTLS and the respective order information from the production control system, enables optimum support by the Cobot at a manual workstation, individually adapted to the respective worker. Due to the integration into the Smart Systems Hub Dresden, the demonstrator can be further used in many ways. As a priority, it can serve as a blueprint for other local companies and demonstrate how collaborative robotics applications can be designed, planned and cost-effectively implemented in production plants.

Due to the rapid spread in everyday life and the great acceptance among users, digital assistants are becoming an omnipresent part of our lives. The success of the intelligent assistants is attributed to the intuitive user interface. Language should be regarded as the most natural form of communication between man and machine. The voice interface allows a casual and easy use of devices even for inexperienced and less tech-savy users. Owing to the complexity of natural language, speech-based assistance systems for control and communication in manufacturing have not been used so far. The objective of the Debuti project is to research the current status of voice-controlles assistance systems in manufacturing, to desing and implement a demonstrator for the control of a robot bysuch an assistant, and to prepare a research project for the use of digital, voice-controlled assistance systems in manufacturing.

Camouflage - Contactless tracking at a manual workplace

Motivation

A general established quality management is the basic prerequisite for ensuring sustainable competitiveness in a manufacturing industry. In times of optimized production, customers require transparency in regard to traceability of individual production steps and used materials and in general the sustainability of manufactured products. Especially for small and medium-sized enterprises (SME), the organizational and technical effort of collecting and processing information presents considerable challenges. High-tech companies, such as the semiconductor and automotive industry rely on direct and automated data acquisition from the machine to the manufacturing execution system (MES). However, SMEs are usually collected data by the operator using a control terminal or paper. The disadvantages of this method are range from partial and complete lack of data, temporal deviations from real processing times to the increase of the risk of data-entry errors by the worker. Order-related and event-driven feedback is often not possible, because the actual production process is thereby interrupted. A consequently and efficient production is impossible.

Objective

The prototype camouflage addresses this challenge with an innovative work design according to the vision of the industrial internet. The camouflage workplace was developed in cooperation with the company CamLine Dresden GmbH. With the help of a software for the real-time analysis of three-dimensional depth data and the connection to an MES, the flow of material can be touchless recorded and monitored at the workplace.

- automated monitoring of material collection and accounting in the IT system of the company

- a partially automated classification of the material by placing the workpiece in defined areas of the assembly area

- the system provides support for the worker in questions relating to the set-up and changeover of the workplace. Acknowledges, what materials in which quantities have been used by the operator. It documents the start, the end and if necessary the break of a work process. Upon request, the system provides an assembly instruction or serial, interactive, real-time help for the operator

- application without constantmedia operation and process interruptions

- contactless and distortion-free recordiing of all necessary information for a complete tracking, a direct check of the current process statur as well as the prompt feedback of prodution orders at the workstation

- continous work flow as well as producer and customer transparency regarding the prodution processes

Motivation

One-third of the global energy is used for the manufacturing of goods. For this very reason, industrial manufacturing is in the focus for efforts to more energy-efficient solutions. The limited available resources and the problems of global warming are challenges which should not be underestimated. Additionally, the increasing energy prices exert pressure on the industrial sector. Today, the energy prices are the second largest cost factor even before labour costs. This is recognized by management worldwide and the majority agreed that the efficiency of all energy sources will be a crucial factor for their company in the next twenty years. Germany attempts to take the leading role here, by encouraging measures to reduce the energy consumption. This strategy is defined within the recommendations for the future project Industry 4.0. Germany is still at the beginning of its efforts. Until now the German industry consumes about 46% of the total energy. Only 10% to 15% of that is used for the actual working steps on the producing machines. Therefore, a great potential still exists.

Objective

The goal of the joint project between University of Applied Sciences Dresden and ccc software gmbh is to analyse and pre-process among others energy consumption, process and sensory measured data with the aid of modern methods and to deduce proposals for action for process engineers, people responsible for the plant plus manager of SMEs. Thus, the managing directors are able to act independently, recognize “energy sinner”, to optimize production sequences or for example to shift the main consumption into time intervals with a low energy tariff. Based on historical data, models will be developed, which will support customers with the planning of an energy-efficient manufacturing. For this, the data have to be pre-processed for further processing, by filtering and adding additional data or transforming them into an evaluable form. Based on this information and with different procedures it is possible to improve the production output at equal or smaller expenditure of energy. A modern manufacturing provides a lot of starting points: For example, the decreased rejects and rectification of them might influence the overall consumption of the company positively. Furthermore, savings potential can be attained by optimizing the process parameter and consequently the expenditure of energy. Because the approaches are independent of the concrete use case, they are applicable to different producing companies. The attempt of this research project is to decrease the energy consumption of SMEs, which already use the software of ccc gmbh, by having a low time exposure and resource effort, which normally need optimizing. Thus, this project contributes to the German goal of energy savings.

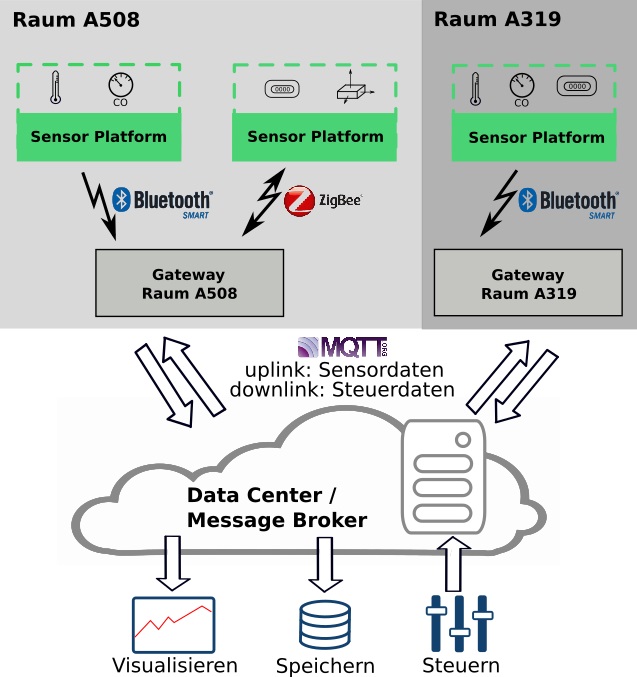

Motivation

Sensors for supervising and securing production processes are becoming increasingly important in the field of factory automation. Currently, available solutions on the market are focusing on external supervision of the manufacturing line. As opposed to this approach, intelligent sensors can localize products, assets and collect environmental information from the production process in order to optimize a path through the manufacturing line. To minimize the dimensions of the sensors it is necessary to decrease the power consumption in order to scale down the size of the energy source.

Objective

The project focuses on the development of a sensor platform, which can be located wirelessly. The platform is able to acquire measurements of its environment and to efficiently transmit them. The development of methods to decrease the energy consumption on the mobile platform is a central project topic. Competences in sensor platform development, indoor localization and data analysis are being combined to reach this goal.

Distributed Production Planning by using heuristic multi-objective optimization algorithms

Motivation

A capable industry is vital for every modern economy. This means, that the ongoing increase of challenges must be met, to ensure a top position in the global market. Therefore, every business has to increase their ability to create its goods and services more individual for each customer, with fewer resources and increased reliability. For example, there are solutions to be invented, that are capable of directing production sequences more efficiently. This doctorate program addresses a part of production planning and aims to develop new measures to calculate a production order for discrete processes. In the end, these methods shall enable enterprises to determine an optimal production order, using fast and cost-effective planning procedures. Additionally, there are multiple target criteria to consider, like; processing times, distribution of work, overall tardiness and energy consumption. All these have to be optimized in some kind. But in most cases, these targets stand in conflict with each other, so a trade-up has to be made. Especially if energy-related objectives are concerned, there is an opportunity to make a contribution to an ecological and sustainable production. This project tackles this problem by using heuristic multi-objective optimization algorithms.

Objective

Multi-objective parallel methods are used to calculate a valid production plan, which is considering different optimization targets. These methods are used to achieve a higher solution quality than traditional approaches. Additionally, the time to achieve a solution can be shortened by using this technique. The aim is using the existing scientific groundwork and extend it to suit the problem at hand. This includes an emphasis on scientific methods for quality insurance, such as validation and verification and a strong focus on ongoing documentation and publication. Moreover, a constant engagement with new achievements in the field is taking place. Reusable, comprehensible and qualitative results can be assured through these measures. To suit these goals, a metaheuristic in form of a parallel multi-objective evolutionary algorithm will be the result of the doctorate program. It shall be capable of producing better results than the current state of the art in less time. Furthermore, it will be adaptable to different problem cases and the method shall be easy to use, tested and documented. There are plans to make the results available under an open-source license, to make it easy for enterprises to use them. In addition to that, there will be a strict division between the simulation and optimization. That makes it possible to exchange either subsystem. The communication between the computing instances will be designed as efficient as possible to reach a good speedup value. The dependencies of the algorithm will be chosen accordingly to make it usable on many different hardware platforms. To make the results reusable beyond that, there will be publications in form of contributions to international journals and conferences. Furthermore, the findings will be presented early to businesses in Saxony. For example, this can be done by presentations in the meetings of the Silicon Saxony group. It is planned to continue the efforts of the project at the professorship of Prof. Reichelt at the University of Applied Sciences Dresden. That concerns the maintenance and extension of the software and further subsequent research projects in the field.

![[Translate to English:] Mitarbeiter reicht einem Roboter eine Gehäuseunterschale](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Projekte/Kobotik_Projekt_KoSeBot.jpg)

![Europa fördert Sachsen [Translate to English:] Förderlogo](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Logos/EFRE_EU_hoch_rgb.jpg)

![[Translate to English:] modell](/fileadmin/HTW/Fakultaeten/Informatik_Mathematik/Forschungsgruppen/Modellfabrik/Bilder/Projekte/Modell_Algorithmen_Webseite.jpg)