Sustainable Polymer Applications

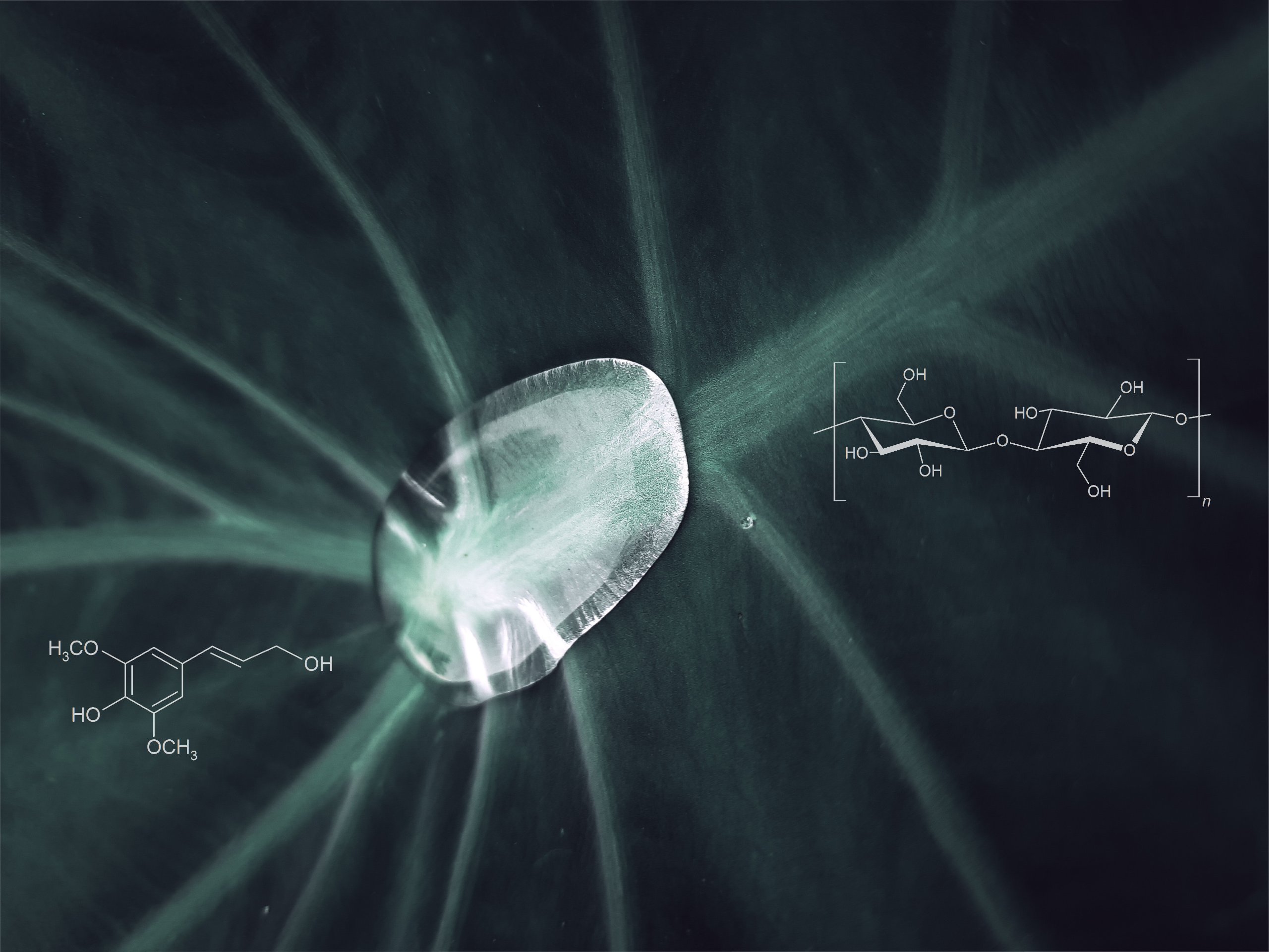

Due to the limited resources of fossil raw materials, intensive efforts are being made to obtain plastics from renewable raw materials. The still inadequate recycling rate of plastics worldwide is fuelling great interest in a whole range of applications in using biodegradable plastics instead of persistent materials, as these are usually compostable, have a better environmental footprint and do not release any harmful or toxic residues during degradation.

Current Projects

Beatrice

The aim of the project is to develop demonstrators of electronic assemblies that are produced from sustainable and biodegradable raw materials as carrier substrates on a technical scale using machines suitable for industrial use.

![[Translate to English:] Teaserbild Beatrice](/fileadmin/HTW/Fakultaeten/LUC/Bilder/Forschung/Chemie/Biopolymere/Beatrice.png)

Ecological Development of Water Bodies

The project team is addressing three aspects of ecological water development with an innovative method for microplastic monitoring, floating vegetation stands made from sustainable modules and the life cycle assessment of the materials used.

![[Translate to English:] Teaserbild Ökologische Gewässerentwicklung](/fileadmin/HTW/Fakultaeten/LUC/Bilder/Forschung/Chemie/Gruene_Gabionen/Bild2.jpg)

Casein

In many countries, there are regions where the groundwater contains high levels of uranium, making it impossible to comply with drinking water limits. Particularly in remote regions and in developing countries, established processes for removing uranium from drinking water (state of the art in waterworks) can hardly be utilised. These problems are to be overcome with the planned application-orientated development work. The aim of the cooperation with Wasserhaus Deutschland GmbH and GICON Resources GmbH is to develop a uranium purification cartridge for drinking water, based on casein for the first time. The starting point is recently published basic results which show that the renewable raw material casein in colloidal dissolved form has a very high binding affinity to uranium (Zänker H. et al., 2019).

bioss.n

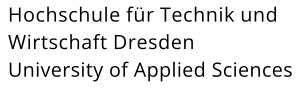

Extreme weather events, climate change and ageing are key factors that lead to the failure of built and natural infrastructure systems. Plants and microorganisms effectively counteract these processes and can significantly increase resistance and resilience. In order to mobilise the full effectiveness of these biological stabilisers, a corresponding period of time is required, which must be bridged by technical measures. The aim of the bioss.n project is to develop a method for securing and repairing erosion-prone and previously damaged areas of infrastructure using biodegradable soil and wall needles. In cooperation between HTWD and Werkzeugbau Winkelmühle GmbH, a material is to be developed that fulfils the requirements for strength and degradation behaviour and at the same time can be processed in real production processes.

Hero

Hero focuses on improving interfacial adhesion, using recycled materials, determining properties after multiple recycling, and new design and recycling strategies for polymer-containing composites.

![[Translate to English:] Teaserbild Hero](/fileadmin/HTW/Fakultaeten/LUC/Bilder/Forschung/Chemie/Biopolymere/Hero_wide_web.jpg)

Rhesis

The RHESIS junior research group explores nature-based solutions and digital methods to enhance the resilience, sustainability and adaptability of the environment and infrastructure in the face of climate change and extreme events.

BioSens

The aim of the project is to develop a biodegradable thin-film sensor system for the simultaneous detection of expansion, moisture and temperature for use in timber construction. The sensor technology intended for permanent monitoring should increase the acceptance and spread of timber construction and not hinder the circular reuse of wood. By using organic electronic components, the project with Institut für Holztechnologie Dresden gemeinnützige GmbH (IHD) and the Dresden Integrated Center for Applied Physics and Photonic Materials (IAPP) of the Technical University Dresden (TUD) is setting an important course towards the development of sustainable electronic sensor technologies with a better carbon footprint than conventional technologies on the market. In addition, all the required materials can be procured in Europe, thus avoiding critical countries of origin and raw materials (e.g. rare earths).

3D printing of electron-modified PLA

Yue Qi is working on the topic of "3D printing of electron-modified PLA" as part of a cooperative doctorate of Technical University Dresden and Beijing Institute of Fashion Technology. The aim of this work is to increase the heat and flame resistance of PLA through the formation of stereocomplex crystals and the use of a bio-based flame retardant. The formation of the crystals is triggered by electron-induced grafting of PLLA and PDLA at low energy using a customised grafting agent.

Finished Projects

The Smart Materials and Electronics for Life (Smart4Life) cluster of the future brings together research and industry partners in the Dresden innovation region, enabling disruptive developments at the intersection of electronics and medicine. Further information is available at:

tu-dresden.de/bereichsuebergreifendes/smart4life

In cooperation with the Fraunhofer Institute for Machine Tools and Forming Technology IWU, HTW Dresden has developed biodegradable functional materials with electrical properties that can replace technology metals such as copper, silver and aluminium in mechatronic components in the future. Combined with biodegradable structural materials, sustainable disposable products are created that no longer need to be recycled, but can be composted and integrated into natural material cycles in line with a biological zero-waste concept (e.g. packaging with RFID tags) or dissolve on the object of use (e.g. washable RFID tags on clothing). Through targeted material customisation, these products are stable over the long term under operating conditions and can also be recycled at the end of the product's life. Under suitable conditions (e.g. moisture, heat, microorganisms), however, they biodegrade completely, so that composting is possible and uncontrolled release into the environment is not critical.

While previous work has been carried out exclusively on a laboratory scale, the future transfer into practice requires the adaptation of materials and processes from a manufacturing point of view.

In the period from 2017 to 2020, the bioESens project qualified graduates of engineering degree programmes in an interdisciplinary group of young researchers for the use, design, development and recycling of products made from bio-based plastics for applications as humidity and piezo sensors. Novel solutions were developed for the use of bio-based plastics in the application field of sensor components, covering the entire value chain from biomaterials, their material modification and processing, application in sensor technologies and functions through to questions of production technology, application testing, durability and environmental compatibility.

The young scientists not only gained qualifications through specialised and interdisciplinary work, for example as part of a doctorate, but also through further training modules in the areas of project management and social skills as well as initial experience with their own teaching activities. At the same time, the project contributed to the transfer of current research results into practice, preferably for regional companies and institutions, opened up new fields of application for bio-based plastics and enabled the interdisciplinary further development of teaching and research in engineering degree programmes. The strong interdisciplinary approach between the Faculties of Agriculture/Environment/Chemistry (Prof. Harre, Prof. Schmidtke), Electrical Engineering (Prof. Bauer) and Mechanical Engineering (Prof. Göbel, Prof. Naumann) under the project management of Prof. Harre should be emphasised as a special feature.

In the MeMoAthero (Mechanism and Model of Atherosclerosis) cooperation project, a drug testing system for a novel treatment approach for atherosclerosis was developed together with Bonn-Rhein-Sieg University of Applied Sciences and Human Biosciences GmbH. As this MeMoAthero project is a collaboration between biologists, chemists, material scientists and engineers, both purely scientific and technical or engineering-scientific work objectives were formulated. In addition to the further development of new marker peptides for diagnostics/early treatment and the development of a simple test system based on a xenogeneic tunica intima with primary endothelial cells in the adapted wound assay model, an artificial scaffold for smooth muscle cells corresponding to the tunica media was developed. In the course of the project, a new, dimensionally stable material made of collagen was developed. The basic material is an inexpensive collagen-based layered material that can be processed on an industrial scale (e.g. by extrusion) and whose technical properties can be controlled by adding certain additives and crosslinkers. This makes it suitable as a film or moulded part for potentially different applications, e.g. tubes. Heat resistance and water vapour permeability are investigated with regard to product-related further processing in the packaging industry using thermal joining and ultrasonic welding processes. Depending on the processing method, 2D and 3D geometries with variable layer thicknesses can be produced. The material, which belongs to the group of collagen composites, has a natural caramel-brown colour, but can also be dyed depending on the application requirements. Patent: DE102017123891

Contact

Lead

Research Associates

M.Sc. Katharina Knez

- A 206

- +49 351 462 2160

M.Sc. Daniel Kranz

- A 211

- +49 351 462 2162

M.Sc. Annabelle Lindau

- A 206

- +49 351 462 2273

M.Sc. Yue Qi

- A 519

- +49 351 462 2097

M.Sc. Ifigeneia Tsetsila

- A 211

- +49 351 462 3273

Dr. rer. nat. Dan Xiao

- A 311

- +49 351 462 2811

![[Translate to English:] BiopolymereUebersicht](/fileadmin/_processed_/7/6/csm_BiopolymereUEbersicht_8077fe5adf.png)

![[Translate to English:] Trinkwasser](/fileadmin/_processed_/e/2/csm_Wasser_web_8874ef2951.jpg)

![[Translate to English:] Holzbau](/fileadmin/_processed_/2/c/csm_Holz_web_37e27c7460.jpg)

![[Translate to English:] PLA](/fileadmin/_processed_/e/b/csm_group-colour-2_b27ebf4d95.jpg)

![[Translate to English:] Kollagenfolien](/fileadmin/_processed_/f/8/csm_roellchen_2d0a95c973.png)

![[Translate to English:] Leiterplatte](/fileadmin/_processed_/f/f/csm_header_bioesens_59749d47e4.png)

![[Translate to English:] 3D-Modell](/fileadmin/_processed_/2/e/csm_MeMoAthero_small_web_cabbdf7c08.jpg)